Process

Main process

- Turning

- Centerless Grinding

- Steel Bar Grinding

- Milling

- Exterior Broaching

- Rolling

- Extrusion

- Others

The ERP process control system operates and monitors each stage of the product starting from the customer’s order reception, throughout the production stages to the final shipment, this way guaranteeing traceability and therefore ensuring quality.

Our Machining Works

Specialize in high production, MIGUMA manufactures precision machined parts for industry based on the needs of our customers.

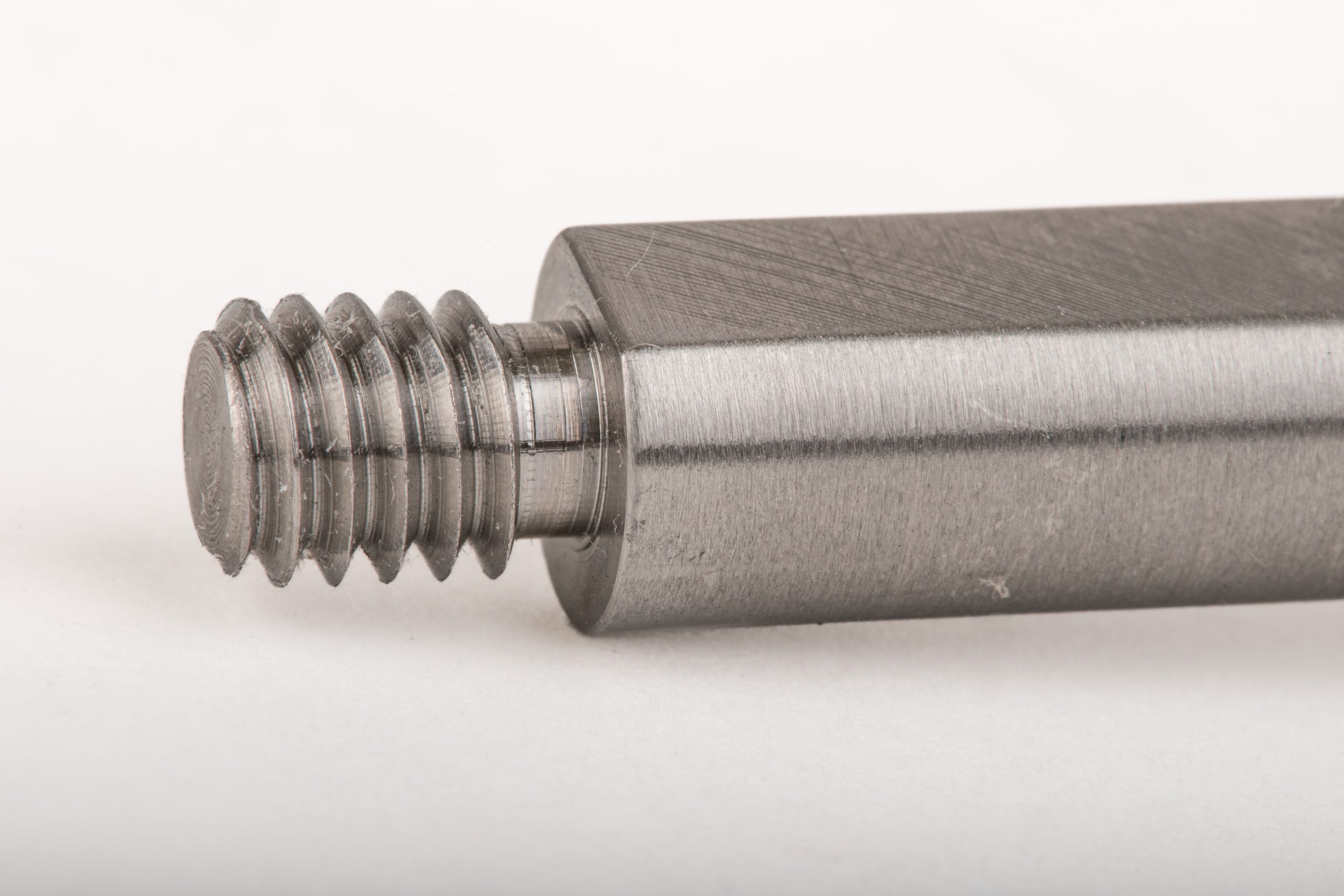

We work with any type of cast iron or alloy materials. We currently manufacture motor shafts, bolts, bushings among others as well as machining motor mounts.

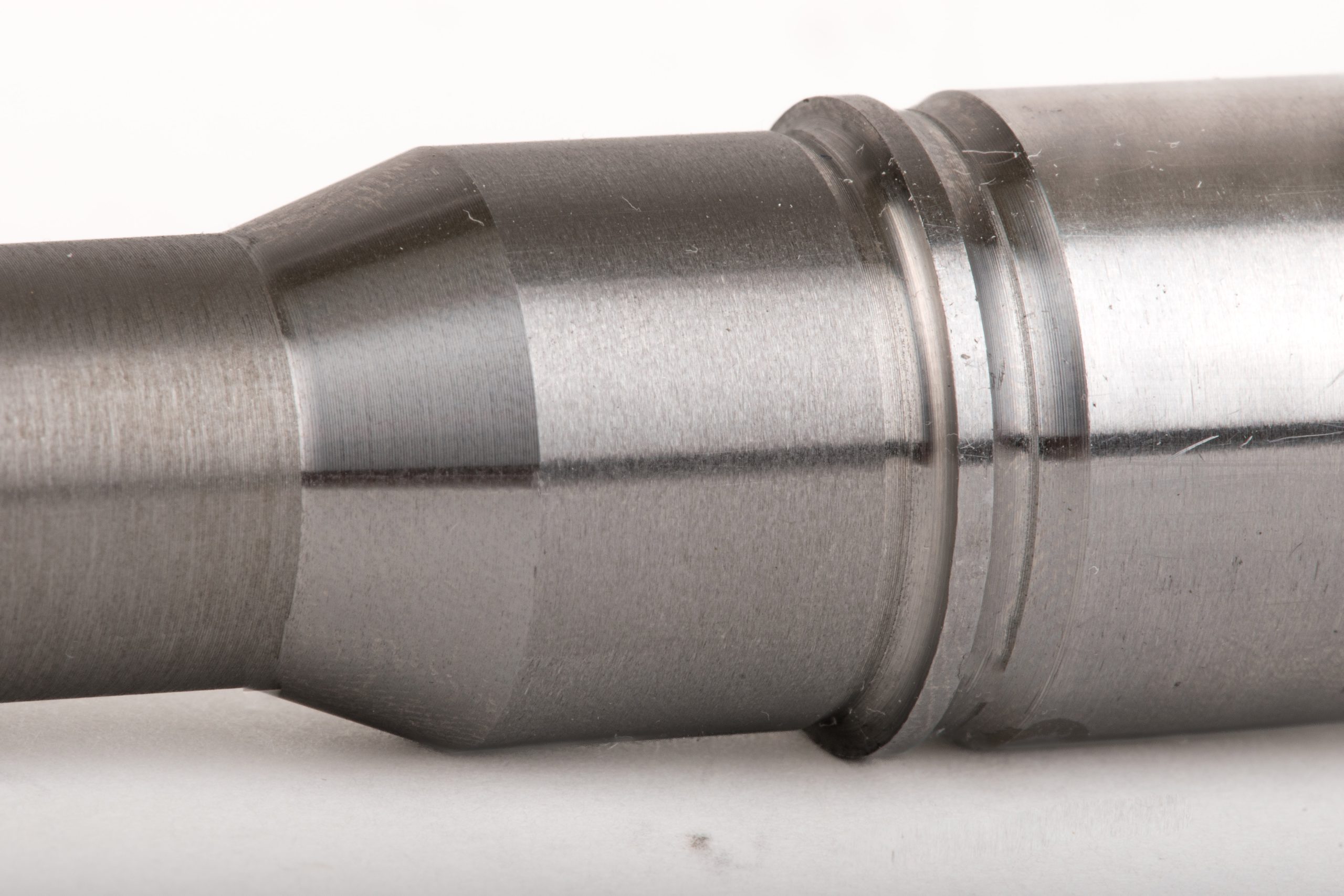

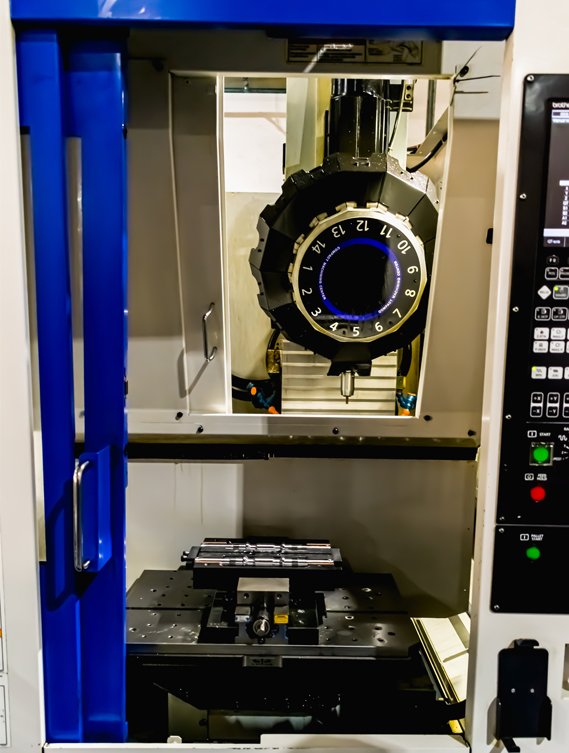

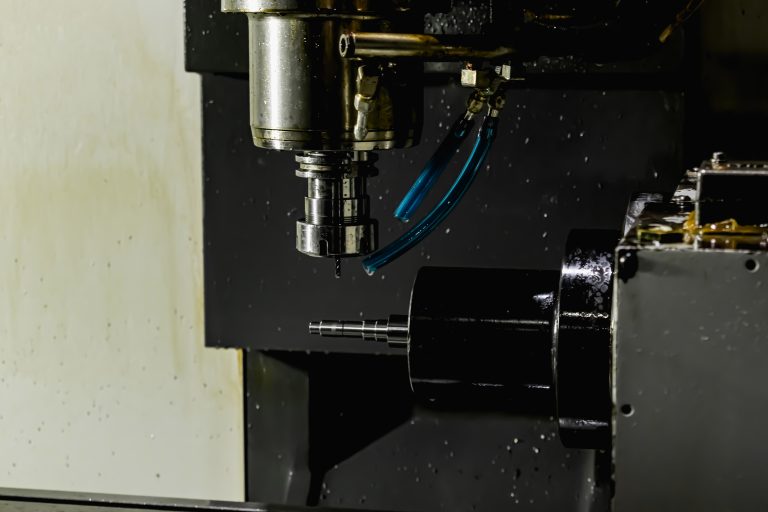

TURNING (CNC, MACHINING CENTER)

Machining process on a CNC lathe or Machining Center used to make cylindrical parts, starting from a certain material (Metals or polymers), in which the cutting tool moves linearly while the workpiece rotates. In this process, a roughing process is carried out (removing a lot of material with little precision) and finishing (removing a little material with great precision).

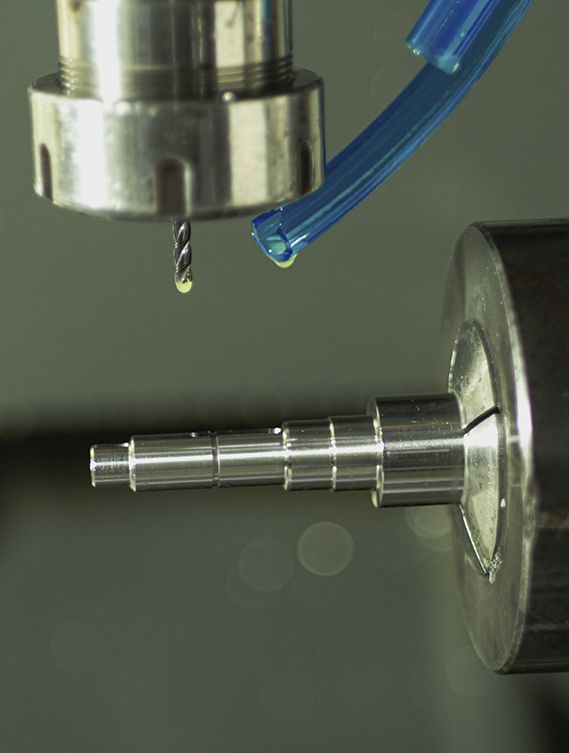

TURNING (SWISS TYPE LATHE)

Automatic lathe machining process with bar feeder, used to make cylindrical parts, starting from a certain material (Metals or polymers), in which the cutting tool moves linearly while the workpiece rotates. In this process, a roughing process is carried out (removing a lot of material with little precision) and finishing (removing a little material with great precision).

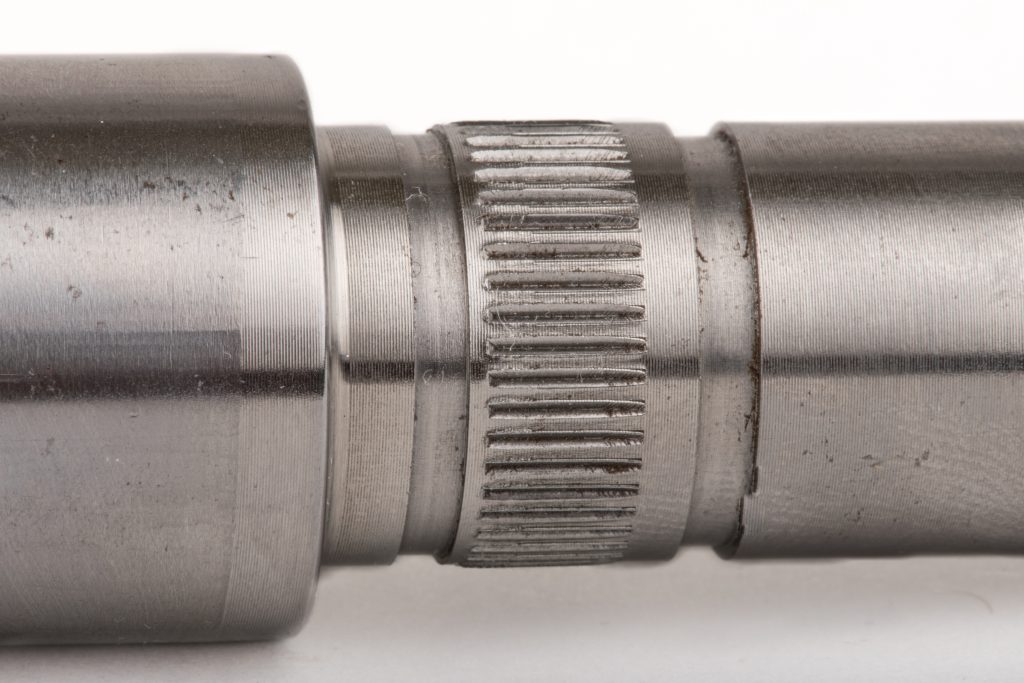

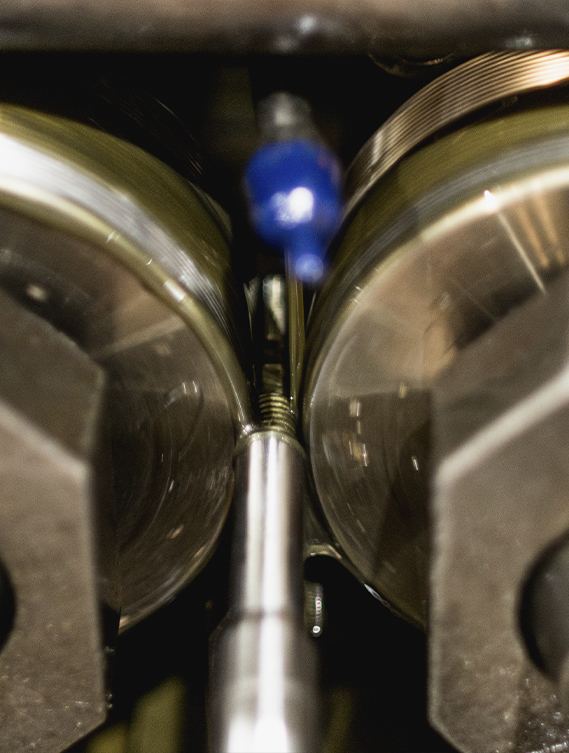

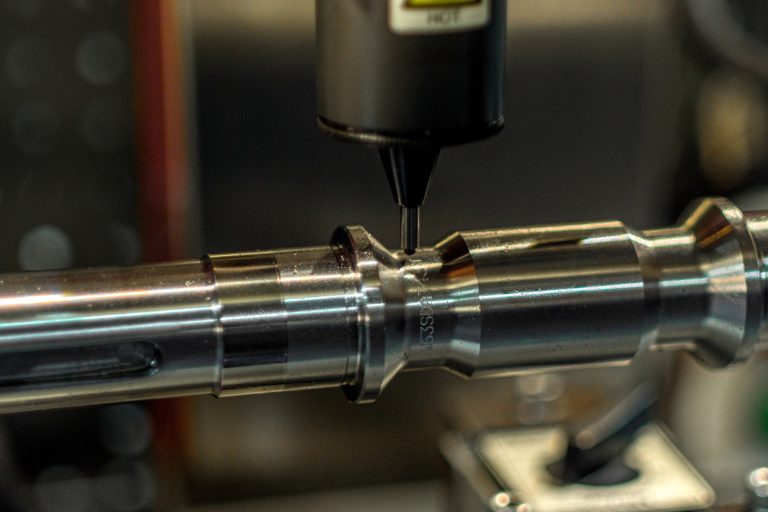

CENTERLESS GRINDING

Metal-mechanical process of grinding external diameters (Larger and Smaller), where the workpiece does not require support between centers to make it rotate against a grinding wheel. In this process, the piece is given roundness, mirror finishes and the required dimensional tolerances

MILLING

Machining operation opposite to turning, because the part remains fixed while the cutting tool is rotating with one or more edges, which, when in contact with the part, progressively eliminate the material.

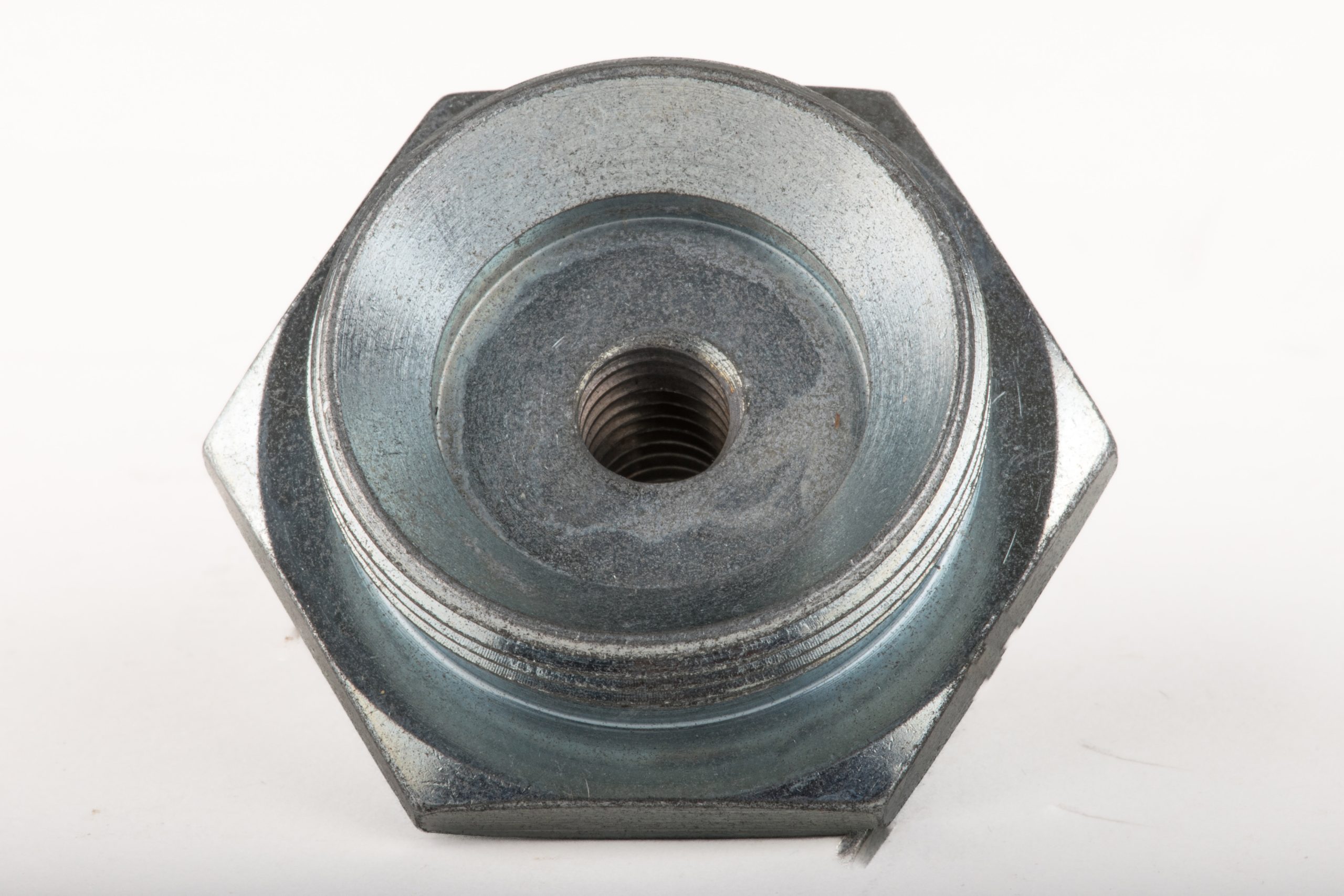

BROACHING

Process by which a rectilineal tool with various edges called a brush is passed over a surface to carve a piece and give it a certain shape.

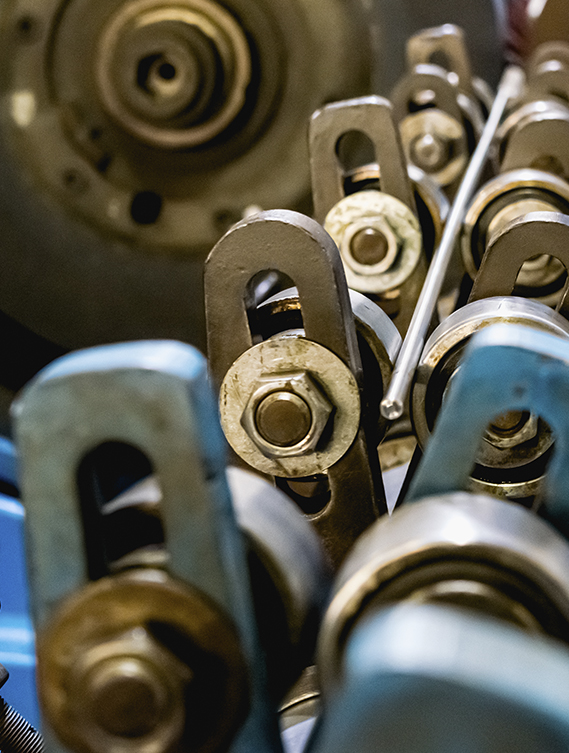

ROLLING

Continuous manufacturing process in which a part is subjected to a series of rollers to provide a specific shape.

- [email protected]

- Calle B No. 500, Parque Industrial Almacentro, C.P. 66600 Apodaca, N.L.